|

products and services...

products and services...

Characteristics Of  Cotton Fabrics Cotton Fabrics

Comfort

The cool comfort of knitted cotton

Unlike synthetic materials, cotton has excellent air permeability and

moisture transmission. It is not subject to static build-up and there

is no uncomfortable clinging to the wearers skin. This is advantageous

in high temparature conditions and when garments are worn for extended

periods of time. Superior comfort is achieved by allowing the body to breath

naturally. Knitted PROBAN�

fabrics are available in lighter weights and in a number of flexible constructions.

|

|

Durability

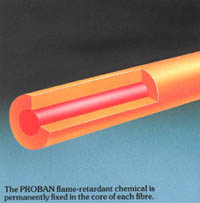

Entrapped within the fibre

Since it was first developed in the 1950's, the PROBAN� process has been

subject to continuous improvement by Albright & Wilson. During treatment,

the PROBAN� chemical is

implanted deep inside the cotton fibres. It is then processed to form an

inert cross-linked polymer which is physically entrapped within the cotton itself.

|

It is this PROBAN�

polymer that gives the fabric its flame retardant performance; and as

PROBAN� does not react

chemically with the cotton fibres, the natural and physical

properties of the fabric remain unaffected.

The PROBAN� polymer

trapped inside the cotton fibres cannot be removed by washing or dry

cleaning, but flame retardant performance may be masked by excessive

soiling or soap deposits. Recommended care instructions should be followed

to ensure the flame retardant performance lasts for the life of the garment.

Chlorine bleaches should never be used during the cleaning process.

|

|

|

Non-combustive Behaviour

The self-extinguishing solution

When flame comes into contact with

PROBAN�

treated cotton, an insulating char is formed and there is no melting,

smouldering or after glow. Unlike synthetics, cotton does not melt away

from a flame to form a hole, nor does it form a hot sticky residue which

can adhere to the skin of the wearer causing burn injury. In foundry and

furnace operations, appropriately constructed

PROBAN� garments, help to protect the wearer against

burn injuries arising from splash by most molten metals (except aluminium

and magnesium). PROBAN�

cotton eliminates the risk of ignition from sparks or flame in welding or

cutting operations. The flame retardant properties of PROBAN� knitted cotton make it

the most appropriate fabric in industries where there is a risk of spillage

and ignition of flammable liquids.

|

|

Quality Control

Albright & Wilson world best practise

The PROBAN� quality control

function is ISO 9002 and EN 45001 accredited. The Albright & Wilson testing

laboratory is one of the most sophisticated in the industry. As the liscensed

PROBAN� finisher, we are

required to submit samples of all

PROBAN� production batches

to the designated laboratory of Albright & Wilson Limited.

|

|

|

|

Here they are assessed for flame retardant performance against the appropriate

standard. Only when a batch meets the standard, is a test certificate issued

together with a supply of the appropriate number of sew-in

PROBAN� labels which state

the flammability performance standard of the fabric.

PROBAN� workwear fabrics

are manufactured to meet all internationally recognised standards for

protection against flame spread and the

PROBAN� label is the

wearer's assurance of PROBAN�

protection.

|

|

Laundering

Total care for the long life of

your garments

To maintain quality and performance levels of your flame retardant garments,

it is imperative the manufacturer's care instructions are adhered to. This will

ensure PROBAN� protection

for the life of the garment.

| |

- Durable flame retardant finish

- Washable and dry cleanable

- Do not use soap

- Do not use chlorine bleach

- Wash in synthetic detergents

|

|

Recommended synthetic detergents:

Castle, Surf, Cold Power, Dynamo, Gows, Radiant, Drive, Fab and Omo

|

|

|

Skin Safe

Ongoing testing ensures your comfort and

safety

Since the introduction of the

PROBAN� process, Albright

& Wilson have commissioned extensive testing of

PROBAN� finished fabrics

to make sure they meet the ever increasing health and safety demands of

society. Following is a detailed look at the program of testing to which

PROBAN� fabrics have

been subjected, by both independant testing organisations and

Albright & Wilson Limited.

|

Leeds University conducted the Human Repeat Insult Patch Test on 256

volunteers wearing PROBAN�

finished fabrics. This test subjects human volunteers to direct contact with

fabrics for various lengths of time. No single case of skin irritation

was found.

|

|

Doctor Martin Scott used

PROBAN� finished fabric

to perform the Human Repeat Insult Patch Test on 100 children. He also

tested children having a typical infantile eczema, where an external

contact was suspected as the cause. Both studies gave a result of no

adverse skin reaction.

|

|

Huntington Research Centre conducted a Dermal Irritation Study on

PROBAN� finished

fabrics. All tests indicated the fabrics were non-irritant to the skin.

|

|

Albright & Wilson subjected 38 volunteers to the Human Repeat

Insult Patch Test for fabrics both before and after laundering. No

case of skin irritation was recorded.

|

|

PROBAN� finished fabrics

were also evaluated using the Kawai S.U.M.P. test on human volunteers. This

test was devised as a more searching examination of dermal effects from

materials that are shown to be non-irritant in conventional tests. An

independant test by the Japanese Society of Cutaneous Health reported

PROBAN� finished

fabrics are non-irritant to the skin.

Continuous testing helps to ensure that up-to-date information is always

available. The most recent studies concerning delayed type skin

hypersensitivity were conducted in 1993 by Safepharm Laboratories in

Derby. PROBAN� finished

fabrics produced a 0% sensitisation rate. This allows the fabrics to be

classified as non-sensitiser, according to EEC regulations. To date,

there have been no published reports of

PROBAN� attributing

to either skin cirritaiton or sensitisation.

|

|

|

Non-toxic

As harmless as common table salt

Although PROBAN� finished

fabric is unlikely to be taken internally, Albright & Wilson have taken

the precaution of testing for the toxicological and environmental impact of

PROBAN� polymer. The

results of tests carried out by the Huntington Research Centre on

PROBAN� polymer extracted

from finished fabric are displayed in the following table.

|

SUMMARY OF TOXICITY TESTING |

|

Compound |

LD 50mg / kg Body-weight |

Route |

|

PROBAN� Polymer |

3200 - 5000 |

Oral |

|

Sodium Bicarbonate |

4220 |

Oral |

|

Sodium Chloride |

3000 |

Oral |

The toxicity levels in the table demonstrate that if a 70kg person ingested

1.5 metres of PROBAN� treated

fabric, it would prove as harmless as an equivalent dose of common table salt.

The PROBAN� polymer present

in the fabric is insoluble in all common solvents and does not present any

hazard to the eyes or by ingestion.

Chemical analysis undertaken by the Medical Research Centre in Britain

discovered that the fumes from charring PROBAN� fabrics were of no

greater toxicity than fumes produced by burning untreated cotton fabric.

A further independant study by the Lambeg Industrial Research Association

concluded that the combustion products produced by PROBAN� fabrics were not

significantly different from those produced by untreated fabrics.

PROBAN� fabrics produced

fewer combustion by-products than untreated fabrics purely by

PROBAN�'s self-extinguishing

nature.

|

Optimum Protection

Knitted Cotton Comfort

Peace of Mind

|

|

Contact us for more details

Call 6781-9933 or Email Us!

|

|

|